MLH Multistage Series

High head MLH series

Double support multistage pumps PN40-64 MLH

Surface pumps with horizontal axis

Possibility of building motor pumps

SECTION

1. bearing

2. support

3. pump shaft

4. stuffing box

5. packing

6. suction body

7. delivery body

8. diffuser casing

9. impeller spacer

10. tie rods

11. diffuser

12. impeller

13. wear ring

Presentation and construction features

A recent design breakthrough has made possible the creation of a new series of multistage pumps that achieve the highest hydraulic yields in their class The MLH series consists of horizontal axis multistage centrifugal pumps equipped with two supports at the ends suitably sized for housing the bearings. The delivery and suction bodies, equipped with support feet, allow mounting the hydraulic core with four strong, highly compact and rigid bolts. The inlets and outlets are adjustable on three sides while the transmission shaft, with two possible counterpoised nibs, allows clockwise or counter-clockwise rotation and coupling in series with several pumps of the same family. The shaft seals, both packing and mechanical, are connected to a compensation system that attenuates the higher working pressures, protecting it from unexpected breakdowns. The impellers, housed in wear rings and dynamically balanced with extreme precision, and the ball bearings, amply dimensioned for the support of radial and axial loads in both directions, confer characteristics of absolute reliability and durability. The MLV series includes groups of monoblock, multistage, vertical axis electropumps. Together with the best axial compensation techniques that do not weigh on the rotor bearings, the excellent hydraulic characteristics of these pumps once again guarantee full, vibration-free, silent-running reliability.

The principal uses for these pumps involve: Conveying water through industrial, municipal water and home systems; snowmaking systems, fire-protection systems, raising pressure and irrigation.

Widths and limits of use:

Axis height standardized UNI 2946 and ISO 496. Sealing on the shaft packing in graphite or teflon.

Mechanical shaft seal standardized to DIN 24960 and ISO 3069.

Pump shaft in stainless steel with protrusion on the suction side in the standard version (clockwise rotation seen from the command side).

Suction mouth PN16 in G25 cast iron; Pressing mouth PN40 and casings in G25 cast iron up to 40 bar of operation; Discharge outlet PN64 and shells in GS400 spheroidal cast iron up to 64 bar of operation.

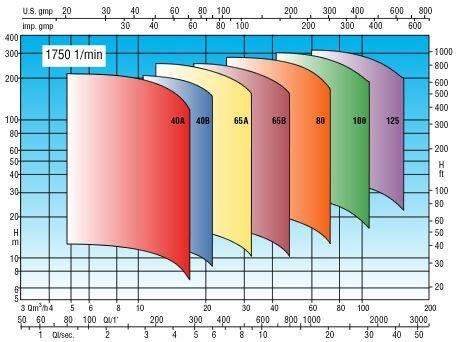

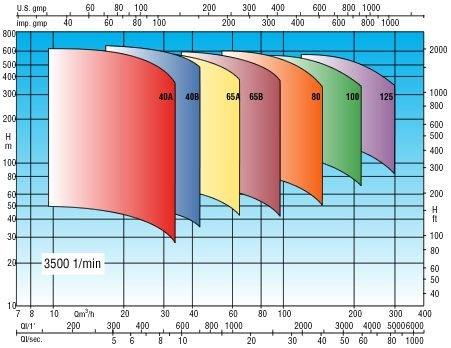

Rotation speed from 1450 to 3500 g / 1 °. Max temperature of the liquid: + 140 ° C.

Liquid pumped chemically and mechanically compatible with the materials used.

- Flow rates up to 300 m3 / h

- Heads up to 640 meters.

- Powers up to 450 kW