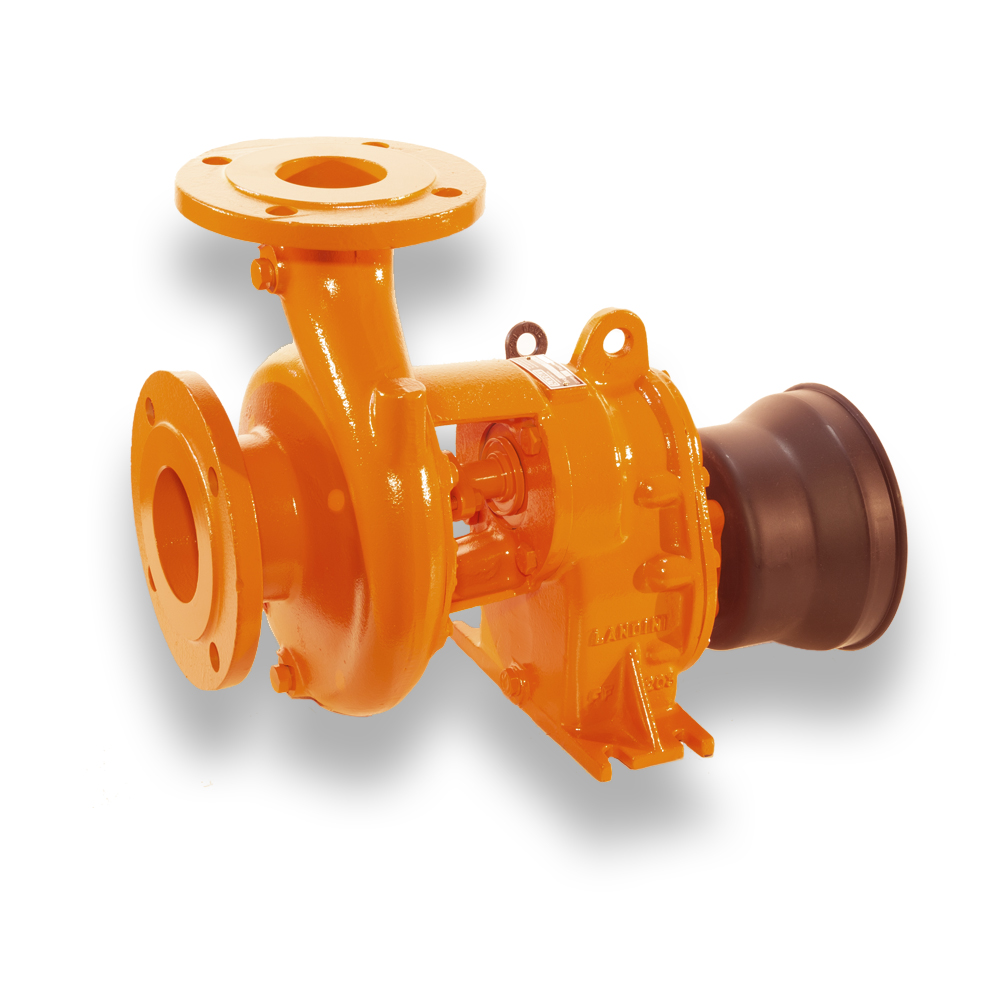

CU Series

CU Serie medium high

Wheeled pumps for single-impeller tractors CU

Surface pumps for power take-off

Centrifugal pumps that can be coupled to tractors by means of a slow power take-off (540-1000 rpm).

Single stage hydraulics.

Uses and limits of use

Irrigation service by means of tractors or lifting of water by different driving forces such as tankers. According to the materials normally used in the production, the CU/CMS pumps are suitable for lifting soft water which is chemically and mechanically not aggressive.

Max. water temperature: 80° C

Max. water hardness: 40 g/m³.

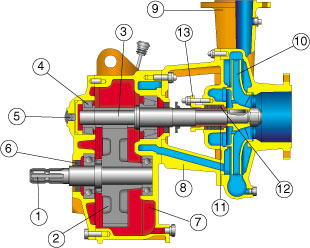

SECTION

1 Power takeoff

2 Driving crown gear

3 Pump pinion shaft

4 Bearing

5 Bearing register

6 Oil retaining ring

7 Overgear-box

8 Spacer

9 Delivery body

10 Impeller

11 Shaft bushing

12 Packing

13 Packing gland

CU SERIES PRESENTATION

This range of pumps with progressive size includes the single-stage pumps with low, medium, high delivery head, series CU, and the two-stage pumps for high pressures, series CMS.

By means of a cardan shaft they are coupled to the power takeoff of the tractors normalized at 540 or 1000 rpm, while the lower part of the overgear-box, suitably shaped, is used as an anchor base for the pump itself. They are mounted on a two-wheeled tubolar trailer or on a base with a three-point coupling.

The wide range of speed ratios makes it possible to obtain specific couplings on any type of tractor or thermic motor equipped with a slow power takeoff, only. Besides being used for all types of irrigation services, these pumps are suitable for lifting water by different motive powers, such as fire fighting tank trucks or tankers for drinking water supplies.

A well-tried water circulation cooling system keeps the overgear at the right operating temperature, also in continuous working conditions and with very high ambient temperatures.

CONSTRUCTION FEATURES:

The hydraulic unit and the overgear-box are made in fine-grained gray cast iron. Inside the overgear-box 4 suitably selected and dimensioned bearings support a helicoidal-shaped gear pair and a power takeoff shaft made in cemented and hardened Ni-Cr alloy steel. . Near the packing, the pinion shaft is protected by a hard-chromed brass bushing which can be easily replaced. The centrifugal impellers are dynamically balanced. . In the two-stage pumps the intermediate diffusers with direction blades and the spiral delivery body are equipped with seal rings which can be easily replaced on each impeller, while the pinion shaft is guided by a support with a bronze journal bearing placed in the suction cover.

USE LIMITS:

According to the materials normally used in the production, the CU/CMS pumps are suitable for lifting soft water which is chemically and mechanically not aggressive. Max. water temperature: 80° C Max. water hardness: 40 g/m³.

Operation by means of cardan shaft, only.

Application on two-wheeled tubular trolley.

Application on base with three-point attachment.