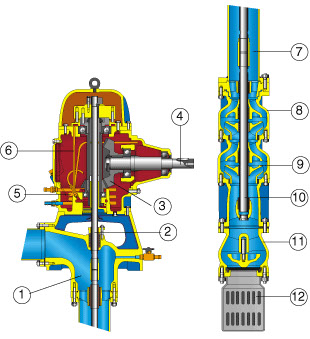

D series with EF control

D Series with EF control – Electric motor

Vertical axis pumps for boreholes D EF

6 “, 8”, 10 “well pumps and electric pumps

SECTION

1. Delivery base

2. Driving shaft

3. Bevel gear pair

4. Power takeoff shaft

5. Cooling coil

6. Lubrication circuit

7. Line shaft

8. Body pump

9. Impeller

10. Pump shaft

11. Foot valve

12. Strainer

VERTICAL AXIS CENTRIFUGAL PUMPS

“D” Serie

CONTROL UNITS - EF SERIES

These drive units allow the direct coupling to electric motors by means of fl anges, normalized according to CEI-IEC-UNEL in the construction frames V1 and with powers up to 55 Kw. Inside they are equipped with one or two grease lubricated ball bearings, according to the unit size, while the vertical driving shaft and the motor shaft are coupled by means of a fl exible coupling. The delivery base and the upper support are made in fine-grained gray iron.

THE PUMPS

Made up of a series of modular stages, they are provided with a fi tting for the upper pipe and normally with a foot valve flanged to a suction rose in galvanized steel which prevents the foreign matter from getting into the suction system. The pump bodies and the valve body are made in fine- grained gray iron, the impellers with semiaxial flow and dynamically balanced, are available in cast iron or in bronze on reques.; the pump shaft guided by wearproof rubber bearings, is in hard-chromed carbon steel or in stainless steel on request.

THE LINE SHAFT

It is formed by a rising steel pipe with double flanged trunks whose standard length is 3 Mt. It makes it possible for the pump to be positioned in depth and to convey water. Driving is performed by rods guided on each end by wearproof rubber bearings which keep a perfect alignment of the driving axle in all installation depth. Near each rubber bearing, the rods are protected by hard-chromed wear brass bushes. The threaded connection sleeves and the rods are made in carbon steel or in stainless steel on request. The rubber bearings are arranged in the middle of a cast iron support placed between the pipe flanges.

USES

Deep water lifting. Installation in boreholes or in the open. Irrigation systems, water systems, industrial and fire-fighting systems.

USE LIMITS

Mechanically and chemically non-aggressive fresh water lifting according to the materials normally used in production.

Max. water temperature: 40° C.

Maximum water hardness: 40 g / m³.

Installation depth: up to 120 mt., in standard execution.