S Series

S Series

Semi-axial cast iron submersible pumps S

Well pumps and electric pumps

Submersible electric pumps composed of:

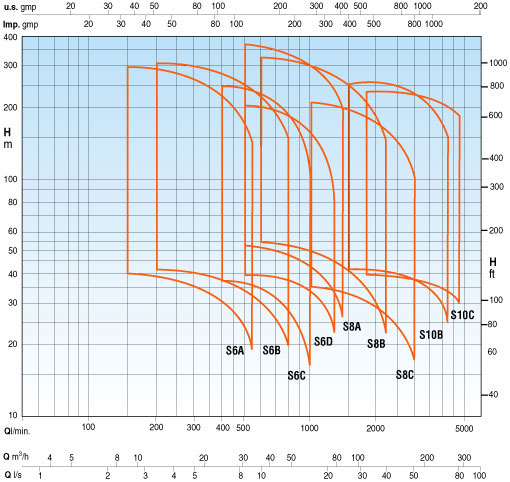

Semi-axial pump consisting of a series of 6 “8” 10 “modular stages.

Submersible motor produced by internationally renowned industries with specific size according to “NEMA” standard.

Possibility of direct or star / delta starts.

Uses and limits of use:

Deep water lifting. Installation in boreholes or in the open.

Sprinkler or flow irrigation systems. Water, industrial and fire-fighting applications.

Water supply for civil use.

Lowering of water table, raising of pressure. Mechanically and chemically non-aggressive fresh water lifting according to the materials normally used in production.

Maximum water temperature: 40 ° C.

Maximum water hardness: 40 g / m3.

Installation depth: up to 250 meters in standard execution.

SECTION

1. Valve body (cast iron)

2. Non-return valve (cast iron)

3. Bearing (rubber/bronze)

4. Wear ring (rubber/bronze)

5. lmpeller (cast iron/bronze)

6. shaft (chromed carbon steel / stainless steel)

7. Body pump (cast iron/bronze)

8. Tile protection cables (stainless steel)

9. Bearing (bronze)

10. Coupling (stainless steel)

11. Suction bowl (cast iron)

12. Shaft (stainless steel)

13. Upper support (cast iron)

14. Bearing (bronze)

15. Stator (electromagnetic lamination)

16. Rotor (electromagnetic lamination)

17. Bearing (bronze)

18. Thrust bearing (bronze/compound synthetic)

19. Thrust bearing-support (cast iron)

20. Lower suppor (cast iron)

SERIES S PRESENTATION

The new submersible electric pumps of a mixed-flow type far 6" 8" 1 O" wells consist of a modular set of components, which allows the performance of high capacities with medium working heads. The pump bowls, made of cast iron, contain the direction blades. The mixed-flow impellers, dynamically balanced and locked on the shaft by conical bushes are made of cast iron or bronze on request. The pump shaft, in hard-chromed carbon steel, is supported by rubber bearings at each intermediate bowl and by a bronze bearing located inside the suction bowl. The latter, made of cast iron, allows the coupling between pump and motor, and protects the shaft coupling. The delivery bowl made of cast iron has a threaded or flanged end and houses the closing non-return valve.

The submersible motor is produced by renowned companies worldwide according to high manufacturing quality standards. The specific size in compliance with "NEMA" standards allows a quick coupling and easy exchange.

USES

Deep water lifting. Installation in boreholes or in the open. Sprinkler or flow irrigation systems.

Water, industrial and fire-fighting applications.

Water supply for civil use. Lowering of water table, raising of pressure.

USE LIMITS

Mechanically and chemically non-aggressive fresh water lifting according to the materials normally used in production.

Max. water temperature: 40° C. Maximum water hardness: 40 g / m³.

lnstallation depth: up lo 250 mt., in standard execution.

CONSTRUCTION ON DEMAND

Impeller, body pump, suction body and valve in bronze. Shaft in stainless steel.

Bearing and wear rings in bronze.