Multistage MS series

MS series multi-impeller pumps

Bare horizontal axis multi-impeller centrifugal pumps that can be coupled to thermal or electric motors by means of an elastic coupling.

Possibility of building motor pumps

USE

Sprinkler irrigation, water supply for civil and industrial use, fire-fighting services and pressure raising.

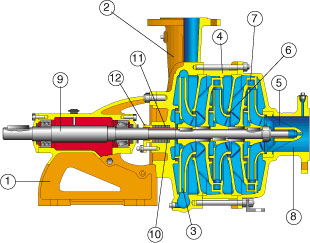

SECTION

1. Support

2. Delivery body

3. Impeller

4. Casing

5. Support with bronze journal bearing

6. Wear ring

7. Diffuser

8. Cover suction side

9. Pump shaft

10. Shaft bushing

11. Packing

12. Packing gland

PRESENTATION MS SERIES

These centrifugal pumps with horizontal shaft are provided with a support with a properly dimensioned anchor base. By means of a drive flexible coupling they are coupled to thermic engines or to electric motors whose revolution speed is generally compatible with that reported on the catalogue. The SD range includes groups of single-stage pumps with low, medium, high delivery head, while the MS range is composed of pumps with diffuser, specially made for high pressures, with two, three or four impellers.

They have been developed after a deep study aimed at finding the very best results in terms of liability and efficiency. The use of high quality materials which are essential for a long-life and the MS/SD wide range have made it possible for these pumps to be applied in the most different fi elds, such as: rain irrigation on stationary and travelling plants, public, civil and industrial water supply, fire-fighting, pressure boosting.

CONSTRUCTION FEATURES:

The materials employed, carefully worked and selected, are fine-grained gray cast iron for the hydraulic unit and for the support, hardened and tempered steel for the pump shaft. In the MS series the intermediate diffusers with direction blades and the spiral delivery body are equipped with seal rings which can be easily replaced on each impeller. The centrifugal impellers are dynamically balanced. Near the packing, the pump shaft which is supported by suitably selected and dimensioned bearings is protected by a hard-chromed brass bushing which can be easily replaced. In the MS pumps, the shaft is always guided by a support with a bronze journal bearing placed in the suction cover.

USE LIMITS:

According to the materials normally used in the production, the MS/SD pumps are suitable for lifting soft water which is chemically and mechanically not aggressive. Max. water temperature: 90° C - Max. water Max. water hardness: 40 g/m3.

Coaxial operation only.

CONSTRUCTION ON DEMAND:

MS / SD pumps can be equipped with different materials such as:

bronze impellers, pump shaft in stainless steel, mechanical seal (except for the MSR pumps).